You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Simple heat shield

- Thread starter dagger

- Start date

T9 man

TC ModFather

Well not wanting to rain on your parade here dagger, firstly many thanks for taking the time to dig this out for us.

As the heat shield is made of aluminium this conducts heat like a sponge absorbs water. A fact brought home to me last year when the first aluminium MapTun front strut brace was resting on the engine bay of my car waiting to be fitted.

It was in the sun for about 10 mins while the mechanic popped into the garage to get some tools. I went to pick it up and have another close admiring glance at it, when the burning sensation caused me to drop it hard on the ground. :amazed: Add a heat deflector foil onto the aluminium or it will be a waste of time. I use a 1000 degree special adhesive foil available from Demon Tweeks.

I believe our very own sleeper here on TC uses a gold foil type version on his monster car.

As the heat shield is made of aluminium this conducts heat like a sponge absorbs water. A fact brought home to me last year when the first aluminium MapTun front strut brace was resting on the engine bay of my car waiting to be fitted.

It was in the sun for about 10 mins while the mechanic popped into the garage to get some tools. I went to pick it up and have another close admiring glance at it, when the burning sensation caused me to drop it hard on the ground. :amazed: Add a heat deflector foil onto the aluminium or it will be a waste of time. I use a 1000 degree special adhesive foil available from Demon Tweeks.

I believe our very own sleeper here on TC uses a gold foil type version on his monster car.

Last edited:

I'm guessing, from the photos, that this is mainly to keep hot engine bay air from being sucked in by the filter. If cold air from outside is ducted straight into the enclosed area around the filter, then this will work pretty well, IMO.

T9's suggestion of adding heat reflecting sheet to the box is a valid one as it will further reduce the air temperature in the air box.

Looking at the photos again there doesn't appear to be a bottom to the enclosure. For this to work properly one should be added.

T9's suggestion of adding heat reflecting sheet to the box is a valid one as it will further reduce the air temperature in the air box.

Looking at the photos again there doesn't appear to be a bottom to the enclosure. For this to work properly one should be added.

Last edited:

MADRod

Road Burner

- Points

- 192

- Car

- Sierra RS Cosworth

That set up works well even in extreme applications.

Cold air is ducted in from the front & inner wing. The bonnet completes the box & has a vent to allow even more cold air. Its very hot on the other side of the metal with a Turbo the size of Venus, but it does its job

Cold air is ducted in from the front & inner wing. The bonnet completes the box & has a vent to allow even more cold air. Its very hot on the other side of the metal with a Turbo the size of Venus, but it does its job

T9 man

TC ModFather

So you have never found the need for any heat deflecting foil then Rod?

the stuff round the heat shield looks the same as the stuff i got around my exhaust manifold as standardI'm sure I can see some on there, even if not over the whole area.

T9 man

TC ModFather

I'm sure I can see some on there, even if not over the whole area.

Thank goodness for that! I spotted that too but the old mince pies are not what they used to be :embarrest:

SLEEPER

Pro Tuner

- Points

- 592

Well not wanting to rain on your parade here dagger, firstly many thanks for taking the time to dig this out for us.

As the heat shield is made of aluminium this conducts heat like a sponge absorbs water. A fact brought home to me last year when the first aluminium MapTun front strut brace was resting on the engine bay of my car waiting to be fitted.

It was in the sun for about 10 mins while the mechanic popped into the garage to get some tools. I went to pick it up and have another close admiring glance at it, when the burning sensation caused me to drop it hard on the ground. :amazed: Add a heat defector foil onto the aluminium or it will be a waste of time. I use a 1000 degree special adhesive foil available from Demon Tweeks.

I believe our very own sleeper here on TC uses a gold foil type version on his monster car.

Im not sure that on a close to standard NA car there would be any gain at all even if it was airtight - and if it isnt i doubt its much practicle use at all to be honest.

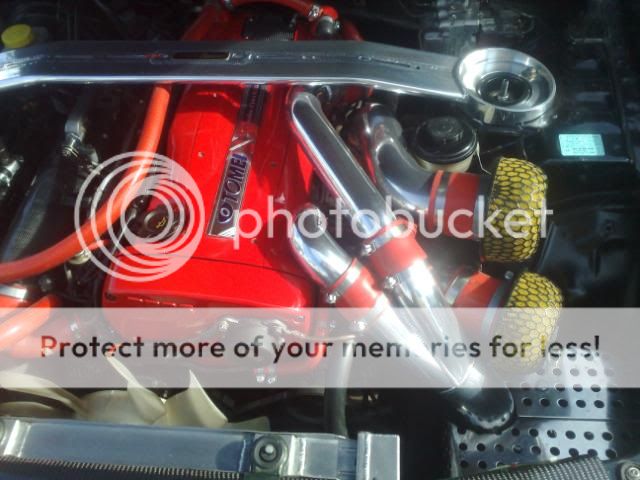

There was a point to mine Nissan RB 26s run pretty hot as standard and with large twin turbos and 1.5 bar boost the heat under the bonnett was quite something and the turbos are close to the air filters which makes things worse.

Before

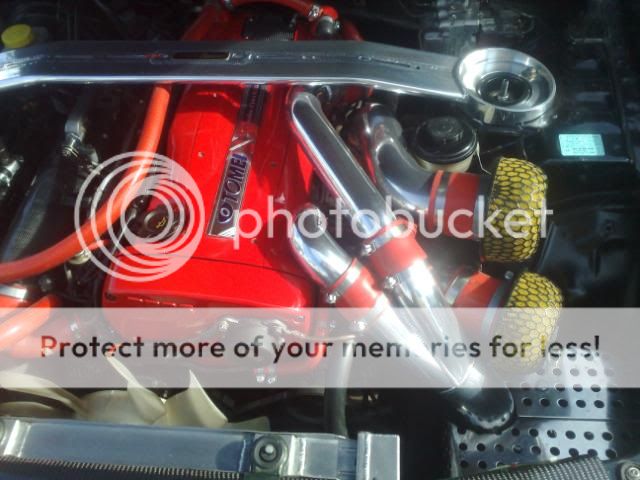

After

Effectiveness depends on NO (or close to) heat getting around or through the box

The box is made up to two layers of carbon sheet with a heat reflective gold sheet on the engine side

I made templates out of cardboard first so the holes for the induction are pretty much air tight .Obviously the fit cannot be rigid as the engine moves so the holes each have a flexible circular rubber seal .

The box is cut exact and sealed at the sides ( the gold sheet is adhesive )

At the top the carbon is cut to the contours of the bonnett and has a door seal which seals to the bonnett "carpet" when shut.

I prefer this because it looks much better without a top.

Air is supplied to the cold box via vents in the Nismo bumper which are specifically for that purpose . I just fabricated ducting to the underside of the cold box so that it is just acts like one large scoop as a direct feed.

How well it works I cant say but it certainly is a lot cooler than the engine bay so worth doing (IMHO anyway :bigsmile

davalav

Pro Tuner

Im not sure that on a close to standard NA car there would be any gain at all even if it was airtight - and if it isnt i doubt its much practicle use at all to be honest.

There was a point to mine Nissan RB 26s run pretty hot as standard and with large twin turbos and 1.5 bar boost the heat under the bonnett was quite something and the turbos are close to the air filters which makes things worse.

Before

After

Effectiveness depends on NO (or close to) heat getting around or through the box

The box is made up to two layers of carbon sheet with a heat reflective gold sheet on the engine side

I made templates out of cardboard first so the holes for the induction are pretty much air tight .Obviously the fit cannot be rigid as the engine moves so the holes each have a flexible circular rubber seal .

The box is cut exact and sealed at the sides ( the gold sheet is adhesive )

At the top the carbon is cut to the contours of the bonnett and has a door seal which seals to the bonnett "carpet" when shut.

I prefer this because it looks much better without a top.

Air is supplied to the cold box via vents in the Nismo bumper which are specifically for that purpose . I just fabricated ducting to the underside of the cold box so that it is just acts like one large scoop as a direct feed.

How well it works I cant say but it certainly is a lot cooler than the engine bay so worth doing (IMHO anyway :bigsmile

Awesome images and a very cool way to do it! But If the air is circulating around the air box, surely the air will start to create a negative flow? I didn't see any where for excessive air to flow through...

davalav

Pro Tuner

Awesome images and a very cool way to do it! But If the air is circulating around the air box, surely the air will start to create a negative flow? I didn't see any where for excessive air to flow through...

Never mind... I am clearly blind. I see a gap underneath for the air... :embarrest:

T9 man

TC ModFather

Never mind... I am clearly blind. I see a gap underneath for the air... :embarrest:

It comes to us all in the end

SLEEPER

Pro Tuner

- Points

- 592

Awesome images and a very cool way to do it! But If the air is circulating around the air box, surely the air will start to create a negative flow?

I didn't see any where for excessive air to flow through...[/QUOTE

I dont think you have undestood the set up ..........maybe thats cos I have not explained it fully .

Put simply the engine bay and cold box are seperate areas and have their own feeds and exits. They cannott therefore affect each other

The air that flows past the engine is it as it would be before the cold box was installed - through the grille , over/round the engine and out under the car as normal

The cold box is fed seperately and kept seperate -

From the vent at the front through ducting to the "cold box". It also has a vent through the inner front wing on the opposite side to the engine. so any excess air can escape that way if it needs to.

The pics also cant show there is a grille at the front of the ducting to stop nasties being sucked up (sticks/ stones / birds / small mammalls etc )

)

I didn't see any where for excessive air to flow through...[/QUOTE

I dont think you have undestood the set up ..........maybe thats cos I have not explained it fully .

Put simply the engine bay and cold box are seperate areas and have their own feeds and exits. They cannott therefore affect each other

The air that flows past the engine is it as it would be before the cold box was installed - through the grille , over/round the engine and out under the car as normal

The cold box is fed seperately and kept seperate -

From the vent at the front through ducting to the "cold box". It also has a vent through the inner front wing on the opposite side to the engine. so any excess air can escape that way if it needs to.

The pics also cant show there is a grille at the front of the ducting to stop nasties being sucked up (sticks/ stones / birds / small mammalls etc

)

)davalav

Pro Tuner

Awesome images and a very cool way to do it! But If the air is circulating around the air box, surely the air will start to create a negative flow?

I didn't see any where for excessive air to flow through...[/QUOTE

I dont think you have undestood the set up ..........maybe thats cos I have not explained it fully .

Put simply the engine bay and cold box are seperate areas and have their own feeds and exits. They cannott therefore affect each other

The air that flows past the engine is it as it would be before the cold box was installed - through the grille , over/round the engine and out under the car as normal

The cold box is fed seperately and kept seperate -

From the vent at the front through ducting to the "cold box". It also has a vent through the inner front wing on the opposite side to the engine. so any excess air can escape that way if it needs to.

The pics also cant show there is a grille at the front of the ducting to stop nasties being sucked up (sticks/ stones / birds / small mammalls etc)

Thank you for the explaination, I understand it better now.

davalav

Pro Tuner

What you want OG is a good flow.

You won't get that with a closed box around a filter the air will stall when the engine isn't under load and i'd imagine this would reduce flow.

It sounds right in my head anyway.

You won't get that with a closed box around a filter the air will stall when the engine isn't under load and i'd imagine this would reduce flow.

It sounds right in my head anyway.

SLEEPER

Pro Tuner

- Points

- 592

I actually agree with OG - I dont think the pressure can build up to a level which would be a problem.

To clarify

I didnt vent the area specifically - the area already had a small slot which vents to the inner wing and therefore to the atmosphere . I just didnt close it off.

Remember I am not claiming any specific power gain just that on high power turbo engines it is a mod worth doing and IMHO if its worth doing its worth doing properly and that has to mean using the right materials.

In fact in my first post Ive said it may well be a waste of time on a standard(ish) NA engine.

To clarify

I didnt vent the area specifically - the area already had a small slot which vents to the inner wing and therefore to the atmosphere . I just didnt close it off.

Remember I am not claiming any specific power gain just that on high power turbo engines it is a mod worth doing and IMHO if its worth doing its worth doing properly and that has to mean using the right materials.

In fact in my first post Ive said it may well be a waste of time on a standard(ish) NA engine.