I had an interesting day yesterday. Started off with removing the door lock from a soon to be scrapped caravan stored next door as it looked identical to our worn out motorhome one. Unfortunately, it wasn't the same.

I was due to meet David at DC Electronics at 2pm so left earlier so I could pop in to the caravan shop in Ulting, but their offerings were no good. Next stop was a quick chat with Geoff Page (my engine guru) prior to meeting David. Geoff said that my car will need to be taken to DCe's place so it can be properly gone over by David and Geoff so they can agree on what needs to be done.

We also decided we would add a G sensor, a steering angle sensor and damper potentiometers. However, we can do away with the speed sensor as we can use one of the wheel sensors.

Met David at 2pm and agreed to the car coming over at the end of August, actual date to be confirmed. I won't know the cost until it has been properly looked at :-(

Next stop was Life Racing in Basildon to drop off my F88 ECU so it can be upgraded to the latest spec. It should be ready in a couple of weeks.

When I got home Julia said that Chris from next door needed my urgent help with an adaptor. Went over to see him and what he wanted was to be able to fit a silencer to a sniper rifle and it had to be done tonight at it was off to the film set early tomorrow morning, so no pressure!

An hour later the silencer was fitted to the rifle

The adaptor isn't actually visible as it is double threaded and joins the silencer to an existing adaptor that had a thread matching that on the rifle barrel.

View media item 4782

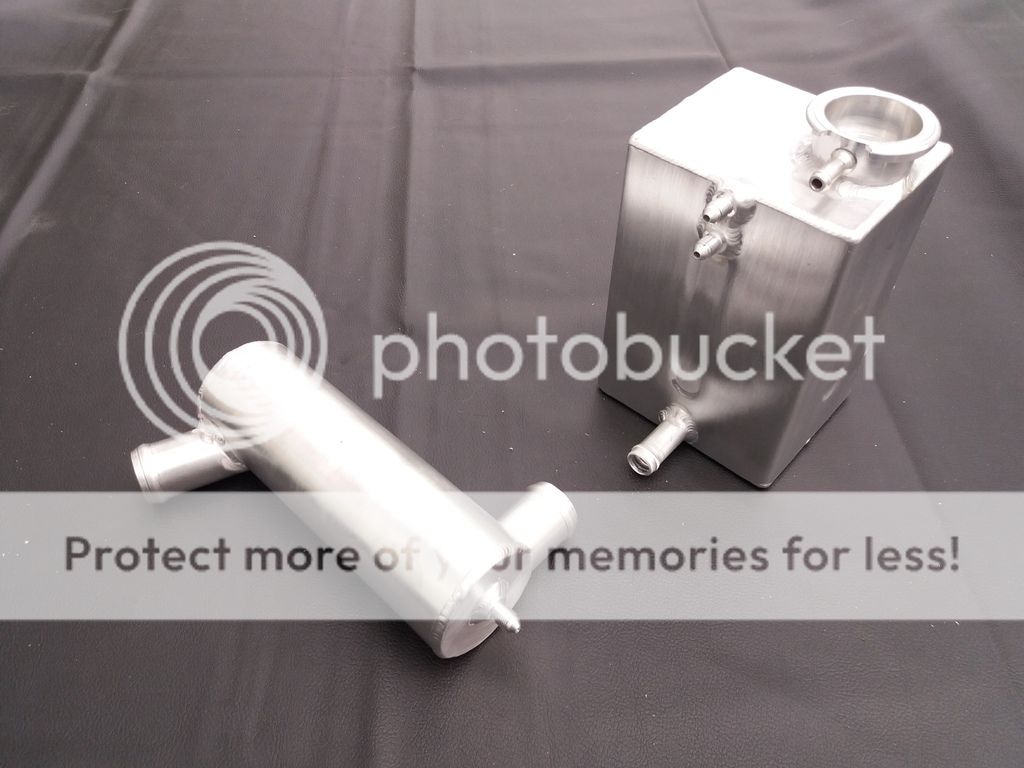

View media item 4783